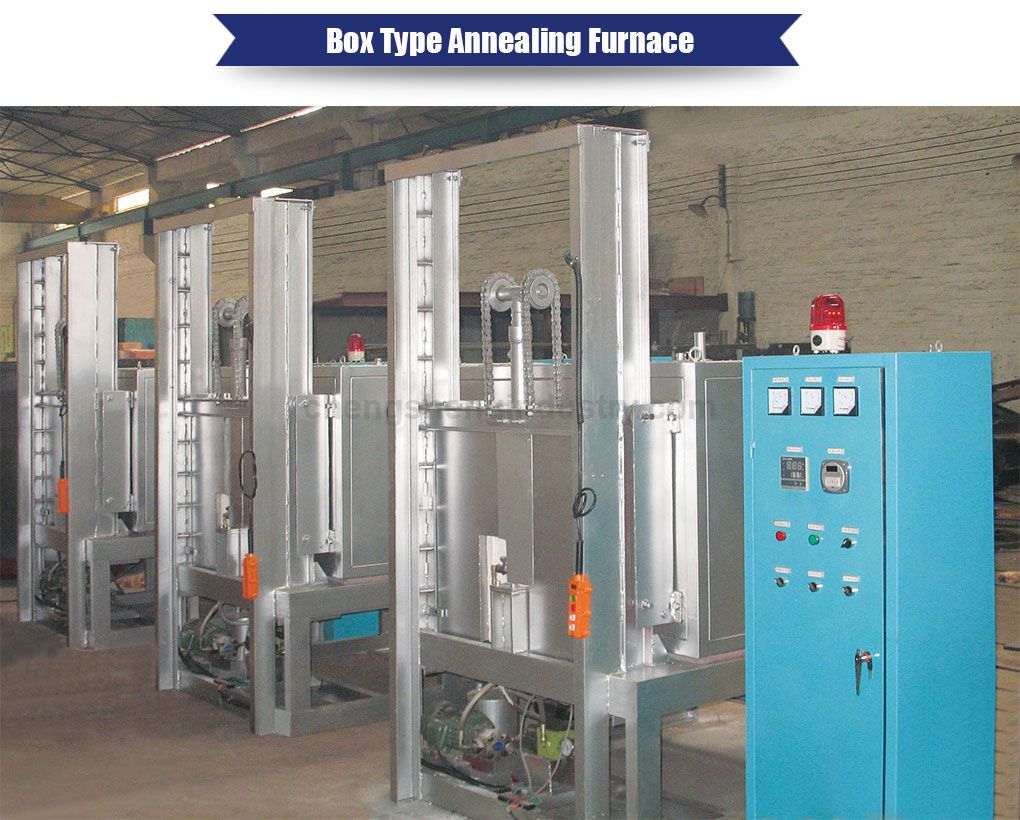

Chamber Type Electric Resistance Heat Treatment Annealing Furnace

Tips:We have Professional R&D engineer, Customized furnaces as your required is welcome.

Brief Introduction:

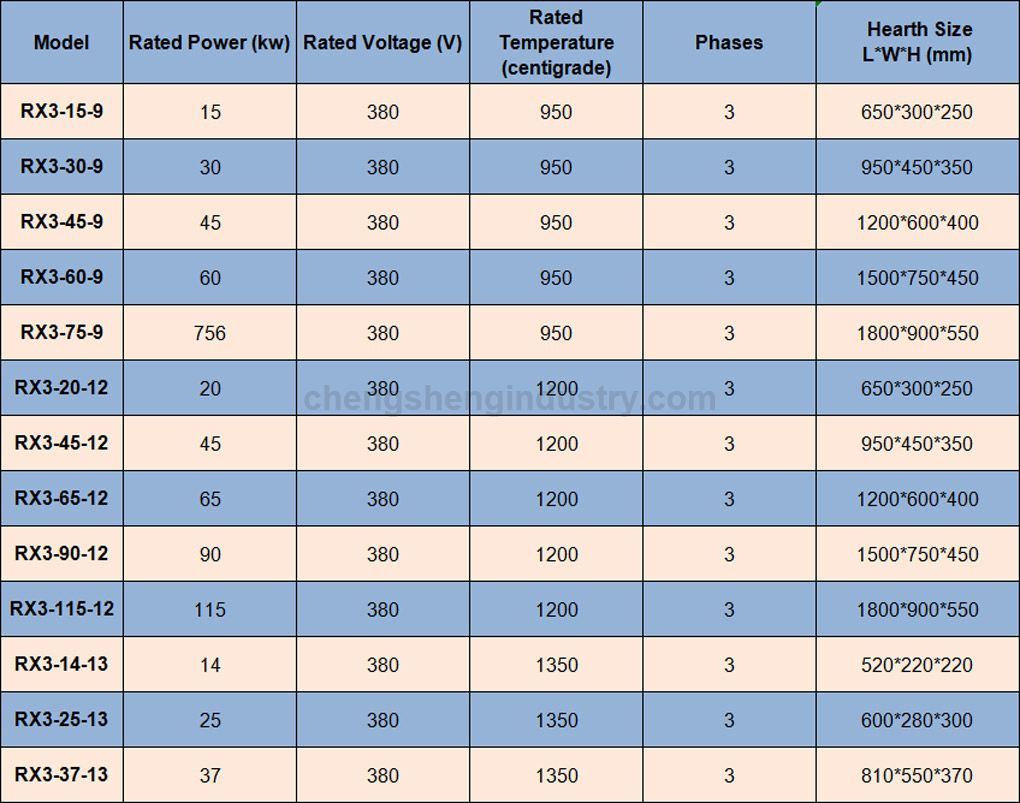

This series of electric furnaces is intermittent operation furnaces which can be used in normalizing, annealing,quenching, tempering, hardening and other heat treatments of carbon steel, alloy steel, high-speed steel and other metal parts. Organic liquid can be dripped into cracking atmosphere of the furnace to realize little-oxidizing heating.

Characteristics:

Adopt mixed furnace lining of ultra-light refractory bricks (0.6/cubic meter) and ceramic fiber, greatly shortening starting heating time and extraordinarily saving energy up to 20%-30%.

Specially-designed furnace door and roller sealing, and built-in heating wire ensure excellent furnace door sealing and uniform furnace temperature.

Double-thermocouple control: one thermocouple is for testing furnace temperature, and the other one is for over-heat protection.

The furnace is equipped with interlock protection device, which can prevent Failure and accident due to misoperation.

Adopt intelligent digital temperature-control system, which feature clear reading, conveniently adjusted, high temperature control precision, easy structure, safe and reliable.

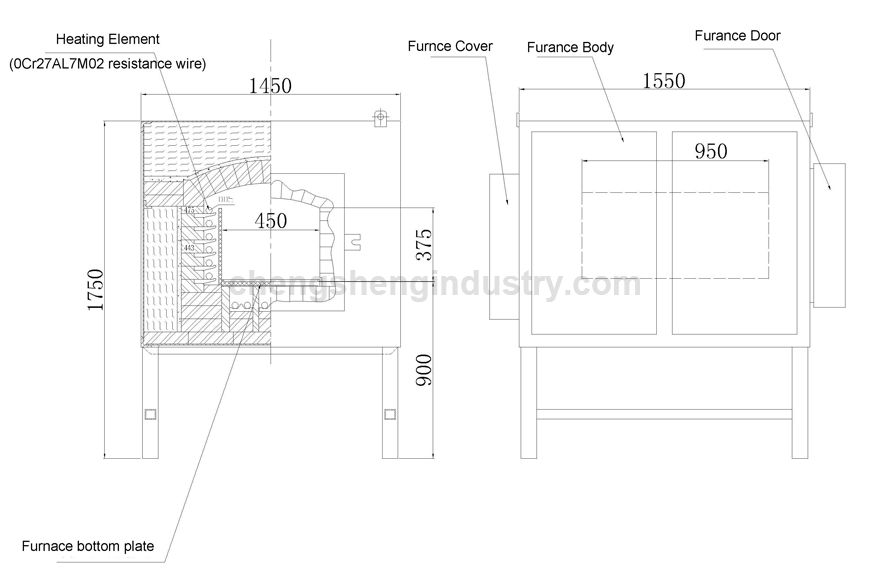

Box Type Annealing Furnace Drawing: