Continuous Mesh Belt Conveyor Heat Treatment Furnace for Annealing

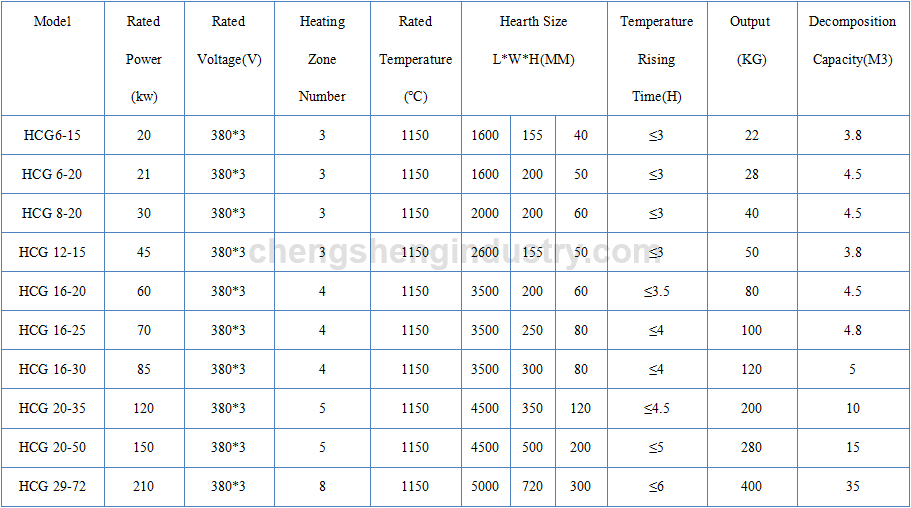

Tips:We have Professional R&D engineer, Customized furnaces as your required is welcome.

Brief Introduction:

The steel belt continuous gas shielded heat treatment furnace is mainly used for the continuous bright quenching of Martensitic stainless steel, bright annealing of austenitic stainless steel ,various copper materials and copper alloy intermediate recrystallization annealing ,final annealing and stress relief treatment, etc.

Structural Composition:

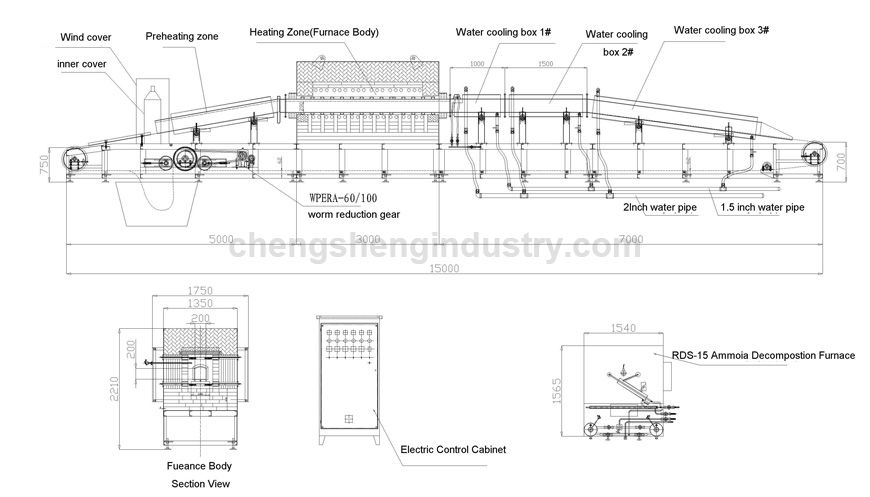

This equipment is mainly composed of transmission system, heating system, cooling system, control system, and ammonia decomposition gas supply system.

Characteristic:

* The furnace boasts stylish design, rational structure, energy saving, high heat efficiency, stable production quality, safe and easy operation, not generating industrial pollution.

* Advanced temperature control : Intelligent thermostat, silicon controlled rectifier and schneider electrical switches ensure temperature control precision of ±1℃;

* The heating hearth (muffle)is made of imported Sweden high-temperature resistance nickel alloy (310S),Ensure that the workpiece after annealing to meet the process requirements;

* Heating elements: High-temp. resistance wire is used, with alumina tube frame; heating elements are arranged in an upper-lower removable to ease repair or replacing; replacing resistance wire has no impact on production;

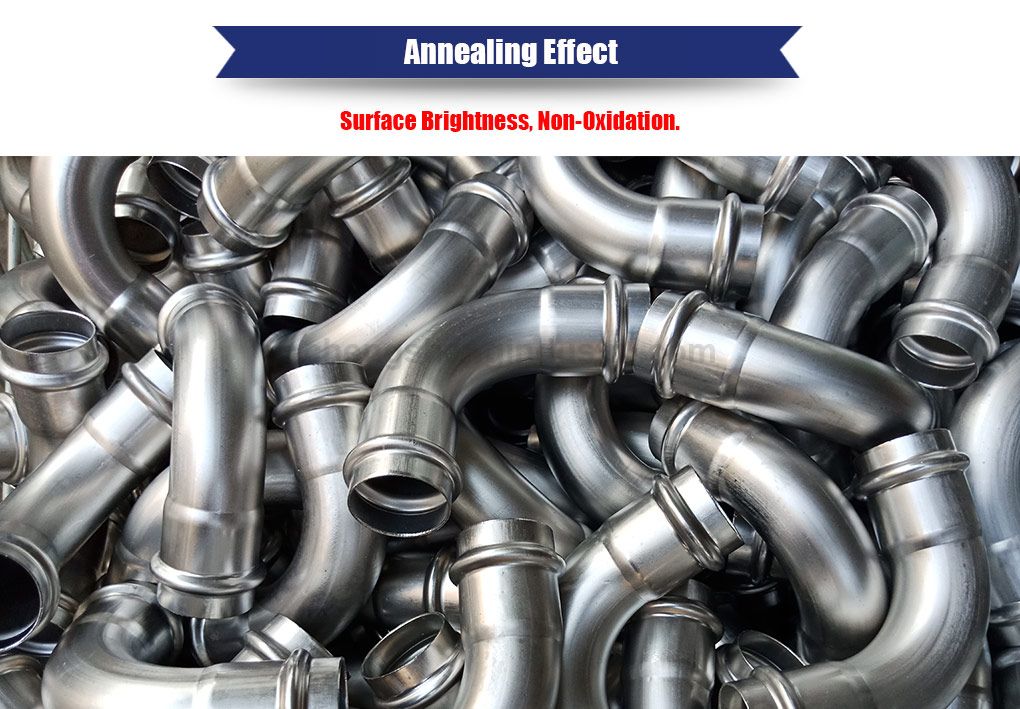

* Protective gas: mixture (hydrogen 75% and oxygen 25%) decomposed from liquid ammonia gets into the hearth and reaches gas protection effect; Product surface will become brightness and won’t be oxidized after heat treatment;

* Steel belt conveying is stepless speed regulating.

Continuous Annealing Furnace Drawing:

1. Mainly used for continuous bright annealing of austenitic stainless steel without oxidation under the high temperature. Such as SUS420J2, 3Cr13, 410, 301, 304, 316, 3156L, 420, S315, 201, 202, etc..

2. Various copper materials and copper alloy intermediate recrystallization annealing, final annealing and stress relief treatment, etc.

3. Can also be used in powder metallurgy sintering, annealing of magnetic materials and some small metal parts. Such as watch case, strap, kitchenware industry of annealing, quenching and stainless steel bright annealing, especially Cr13 stainless steel quenching, stainless steel solid solution treatment, etc.

Copper & Brass Annealing

Stainess Steel Product

Pipe & Tube Annealing

Other Stainless Steel Annealing

-

Mauritius Copper Tube Bright Annealing Furnace

-

India Stainless Steel Stamping Parts Bright Annealing Furnace