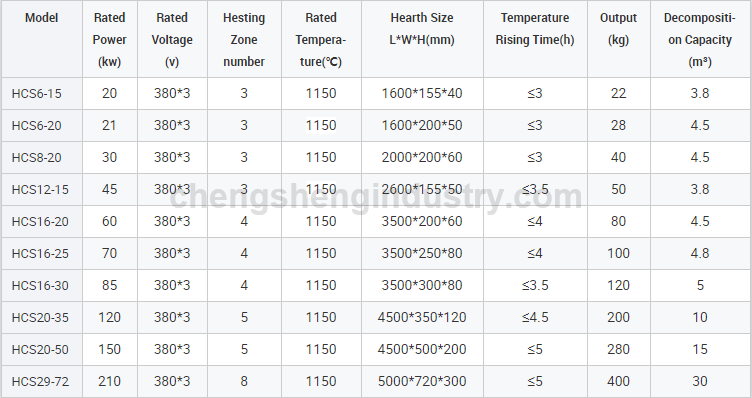

Deep Drawing Parts Controlled Atmosphere Annealing Furnace

Tips:We have Professional R&D engineer, Customized furnaces as your required is welcome.

Brief Introduction:

This continuous controlled atmosphere bright annealing furnace is mainly used for the continuous bright quenching of Martensitic stainless steel, bright annealing of austenitic stainless steels. After suffering from such equipment treatment, product surface becomes bright without oxidation. The furnace boasts stylish design, rational structure, energy saving, high heat efficiency, stable production quality, safe and easy use, not generating industrial pollution. Advanced temperature control manners: Intelligent thermostat, silicon controlled rectifier and Schneider electrical switches ensure temperature control precision of ±1℃. It's advanced, reliable, practicable and cost effective as an industrial furnace.

This device is mainly composed of transmission system, heating system, cooling system, control system, and ammonia decomposition gas supply system. The muffle furnace is made of imported high-temperature resistance nickel alloy(310S) by pressing welding; dismountable electric heating elements can upper-lower heat; steel belt conveying is stepless speed regulating; the gas mixture (hydrogen 75% and nitrogen 25%) decomposed from liquid ammonia gets into the hearth and reaches gas protection effect; the gas direction regulating device ensure stable atmosphere. Having treated by this kind of furnace, product surface will become bright and won’t be oxidized. All treated products will reach excellent consistency.

Characteristic

● Adopt for heat-resistance stainless steel belt or mesh belt transmit the heat treatment workpieces to pass through heating zone and cooling zone. And inject insert gas or gas ammonia decomposition as a protective atmosphere to prevent and avoid the workpiece oxidation in the process of heating and cooling, to ensure the stainless steel surface brightness, no oxidation, no scratches.

● Furnace hearth (i.e. heating zone or muffle) adopt for imported Sweden heat-resisting temperature nickel metal (310S) to ensure that the workpiece temperature come down to technical requirement when outlet.

● Add two pieces soft flange on the between preheating zone, heating and cooling zone, to make muffle in high temperature continuous work with sufficient space expansion and twisted, and the muffle bottom cannot concave-convex wave ,arch and bending. Keep the steel belt( mesh belt) contact the bottom of the furnace to improve the muffle and steel belt (mesh belt ) working life.

● With reasonable structure of heating, uniform furnace temperature, workpiece on the conveyor belt running smoothly, little deformation. Furnace hearth size can be according to customer's different size of the product and production design and manufacturing, with a strong specificity and generality.

● Channel furnace overall appearance is "bridge" structure, front-back inlet and outlet chamber using high quality materials into intermediate sandwich pipe body; The front and back working face with horizontal line to be a certain angle, the angle design is 9 °. Its advantages: to saving protective atmosphere consumption, reduce the production cost.

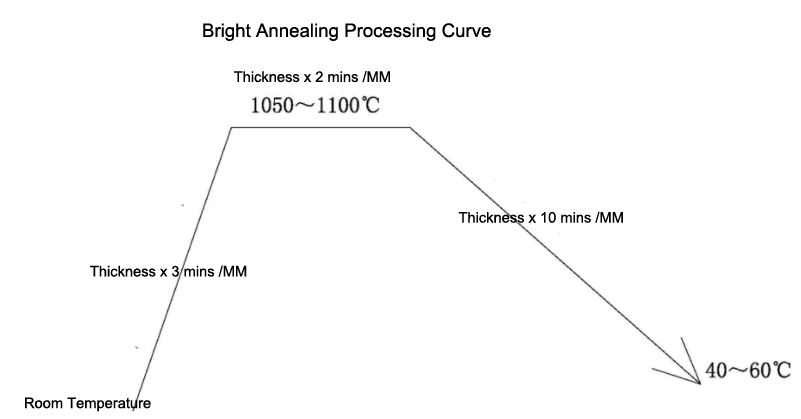

● Adopts advanced frequency control of motor speed conveyor belt control system, realize the stepless variable speed drive of components, precisely control the workpiece in the running time of the heating zone, ensure the bright annealing heating curve accurate implementation.

● Equipped with modern energy-saving type ammonia decomposition furnace

Annealing Process Curve Graph

Stainless Steel Products Bright Annealing