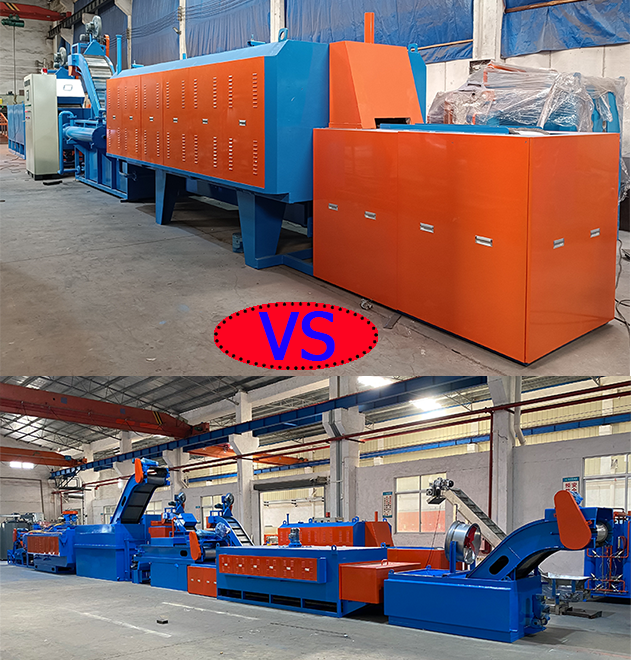

Comparison between Two Type Mesh Belt Carburizing Quenching Furnace-1

Nov. 11, 2025

I. Structural and Design Differences

Muffle-Free Mesh Belt Furnace

Furnace Chamber Structure: It features no enclosed muffle can, with an open or semi-open furnace chamber. Temperature uniformity is achieved through radiation tube heating or convection from a circulating fan.

Mesh Belt Design: The mesh belt moves back and forth in the upper and lower parts of the furnace body, experiencing minimal cold-hot alternating stress and thus having a long service life.

Sealing Performance: The furnace body has poor sealing and relies on a flame curtain sealing device or gas management system to maintain the furnace atmosphere.

Muffled Mesh Belt Furnace

Furnace Chamber Structure: It employs a metal inner liner (muffle pot) to enclose the furnace chamber, isolating the heating elements from the workpieces and reducing oxidation and atmosphere contamination.

Mesh Belt Design: The mesh belt circulates from inside the furnace to outside, experiencing significant cold-hot alternating stress and requiring regular replacement.

Sealing Performance: The furnace body has good sealing, resulting in low gas consumption and a short atmosphere balancing time.

II. Performance Comparison

Heating Efficiency and Uniformity

Muffle-Free Furnace: It achieves good temperature uniformity through radiation tube heating and convection from a circulating fan. However, the open furnace chamber may lead to heat loss.

Muffled Furnace: The muffle can isolates the heating elements, reducing heat loss and providing superior temperature uniformity, making it particularly suitable for high-precision heat treatment.

Atmosphere Control

Muffle-Free Furnace: Due to poor furnace sealing, it requires a continuous supply of protective gas to maintain the atmosphere, resulting in high gas consumption.

Muffled Furnace: The muffle can isolates the furnace from external air, leading to a short atmosphere balancing time and more stable carbon potential control, making it suitable for processes with high atmosphere requirements (such as carburizing).

Maintenance and Service Life

Muffle-Free Furnace: The heating elements (such as radiation tubes) are easy to maintain, but the furnace sealing requires regular inspection; the mesh belt has a long service life.

Muffled Furnace: The muffle can requires regular replacement, resulting in higher maintenance costs; the mesh belt has a shorter service life due to significant cold-hot alternating stress.