Can the mesh belt used in heat treatment furnaces be applied to casting machines

Dec. 18, 2025

The mesh belts used in heat treatment furnaces generally cannot be directly applied to casting machines, as there are significant differences between the two in terms of functional requirements, material properties, design structure, and operating environment. The specific analysis is as follows:

Differences in Functional Requirements

Heat treatment furnace mesh belts: Primarily used for heat treatment processes such as quenching, tempering, and annealing of parts, they need to withstand high-temperature environments and maintain stable operation while ensuring that parts do not deform or become damaged during transportation.

Casting machine mesh belts: They need to adapt to processes such as metal melting, pouring molding, and casting cooling treatment, and must withstand the impact of liquid metal, the weight of high-temperature castings, and corrosive substances that may be generated during the casting process.

Material Property Requirements

Heat treatment furnace mesh belts: They are mostly made of materials such as stainless steel and heat-resistant steel, with high-temperature resistance, corrosion resistance, and high tensile strength as their main characteristics. For example, materials like 304 stainless steel and 316 stainless steel can still maintain good mechanical properties at high temperatures.

Casting machine mesh belts: They need to withstand higher temperatures and more severe corrosive environments, so the selection of materials is more stringent.

Differences in Design Structure

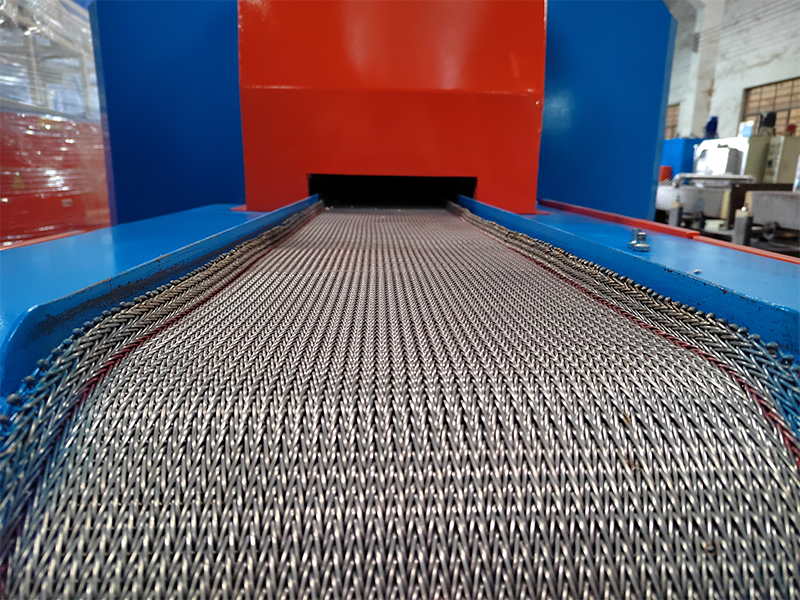

Heat treatment furnace mesh belts: The design focuses on the flatness and corrosion resistance of the mesh surface to ensure the stability of parts during transportation and the effectiveness of heat treatment. The mesh belt structures are mostly crankshaft type, straight shaft type, B-type, herringbone type, etc., to adapt to the shapes and sizes of different parts.

Casting machine mesh belts: The design needs to consider the impact of liquid metal and the weight of castings, so the mesh belt structure is more robust, and the edges may be equipped with baffles or folded edge structures to prevent material from slipping off. At the same time, the mesh belt needs to have higher tensile strength and elongation to adapt to the larger deformations that may occur during the casting process.

Adaptability to Operating Environment

Heat treatment furnace mesh belts: The operating environment is relatively stable, with a small range of temperature variations, and heat treatment is usually carried out in a protective atmosphere or air.

Casting machine mesh belts: The operating environment is more severe, requiring resistance to high temperatures, corrosive substances, and possible mechanical impacts.