How to select the heat treatment process for stainless steel liquid cooling tubes

Feb. 04, 2026

Stainless steel liquid cooling tubes need to choose the corresponding heat treatment process based on the material type to optimize corrosion resistance, mechanical properties and dimensional stability. The specific treatment methods and analysis are as follows:

I. Core heat treatment process selection

Solution treatmen

Purpose: dissolve the carbides that are precipitated during welding or processing to avoid corrosion caused by intergranular chromium deficiency; homogenize the structure and improve dimensional stability. Parameters:

Heating temperature: 1050 - 1150℃ (for stainless steel 304, use 1080 - 1120℃; for stainless steel 316, use 1100 - 1150℃);

Heating and holding time: 1-3 minutes per millimeter (wall thickness);

Cooling method: rapid water cooling (rapid cooling below 500℃ to prevent the re-precipitation of carbides).

Applicable scenarios: corrosion-resistant liquid-cooled pipes (such as in chemical, food machinery, and medical equipment fields).

Strain relief treatment

Purpose: to reduce residual stress from welding or processing, avoiding deformation or cracking of the liquid-cooled pipe during subsequent use due to stress release; to reduce the risk of stress corrosion cracking. Parameters:

Austenitic stainless steel: heating temperature 250 - 400℃, holding for 1 - 2 hours, air cooling or slow cooling;

Ferritic stainless steel: heating temperature 600 - 800℃, holding for 2 - 4 hours, slow cooling;

Martensitic stainless steel: heating temperature 550 - 650℃, holding for 1 - 3 hours, air cooling.

Application scenarios: liquid-cooled pipes with high dimensional accuracy requirements (such as pipes for automated equipment, sensor sleeves).

II. Targeted treatment for special scenarios

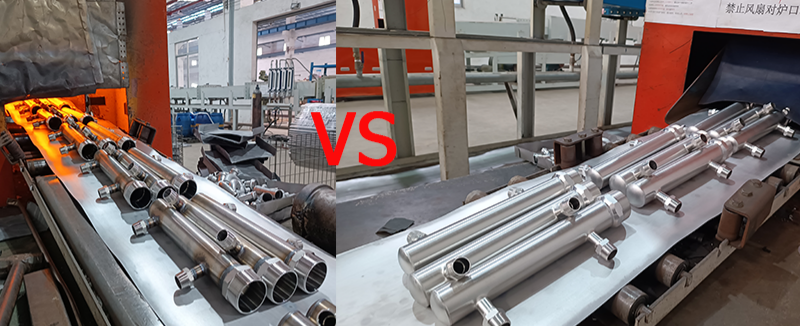

Bright annealing (for liquid-cooled pipes with high surface quality requirements)

Purpose: to eliminate stress, improve the structure, while ensuring no oxidation or decarburization on the surface (meeting surface requirements for food, medical, decoration, etc.); Parameters:

Heating temperature: 700~900℃ (for austenite, 800~900℃; for ferrite, 700~800℃);

Heating time: 1~2 hours;

Protective atmosphere: introduce ammonia decomposition gas;

Cooling method: slowly cool down to below 200℃ in the protective atmosphere, then air cool.