What heat treatment is required for SDS screws

Dec. 11, 2025

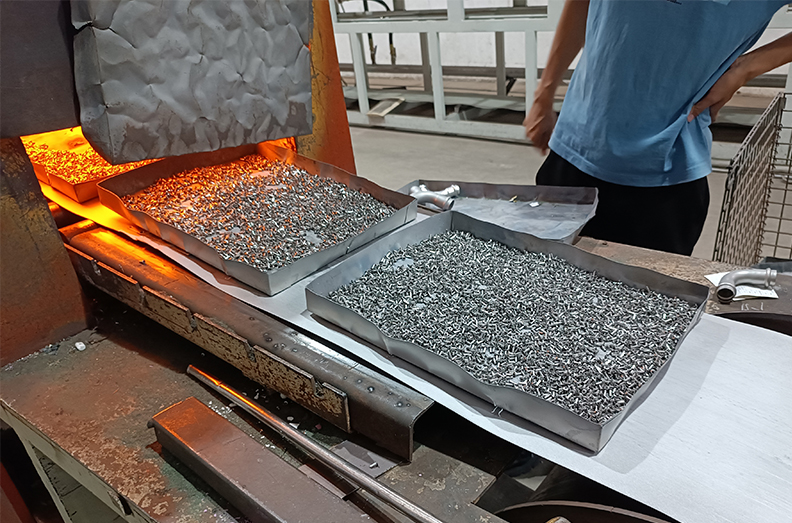

SDS screws (usually referring to screws with high strength or special performance requirements) generally require quenching and tempering treatment (quenching + high-temperature tempering) to achieve good comprehensive mechanical properties and meet usage demands such as high strength, high toughness, and fatigue resistance. The following is a detailed explanation:

Functions of Quenching and Tempering Treatment

Enhancing Strength and Hardness: The quenching process forms martensitic structure in steel through rapid cooling, significantly increasing the hardness and strength of the material.

Improving Toughness and Plasticity: The high-temperature tempering process eliminates quenching stresses and adjusts the microstructure, enabling the material to maintain high strength while possessing good toughness and plasticity.

Optimizing Comprehensive Performance: Screws subjected to quenching and tempering treatment can better resist impact, fatigue, and wear, making them suitable for engineering applications that involve complex loads and harsh environments.

Key Process Points of Quenching and Tempering Treatment

Quenching:

Heating Temperature: Typically heated above the critical temperature of the steel, with the specific temperature determined based on the type of steel and performance requirements.

Cooling Method: Rapid cooling is achieved using quenching media (such as oil, water, or polymer solutions) to form martensitic structure.

Tempering:

Heating Temperature: Select an appropriate tempering temperature based on the desired hardness and toughness, usually ranging from 500℃ to 650℃.

Holding Time: Ensure sufficient tempering of the material to eliminate quenching stresses and adjust the microstructure.

Cooling Method: Generally, air cooling or slow cooling is adopted to avoid generating new stresses.

Special Considerations for SDS Screws

Material Selection: SDS screws are typically manufactured from medium-carbon steel or alloy steel, which exhibit good hardenability and tempering stability, making them suitable for quenching and tempering treatment.

Surface Quality: During the heat treatment process, attention should be paid to protecting the surface quality of the screws to avoid defects such as oxidation and decarburization, ensuring the corrosion resistance and appearance quality of the screws.

Dimensional Accuracy: For SDS screws with high precision requirements, deformation during the heat treatment process needs to be controlled to ensure dimensional accuracy and shape stability of the screws.